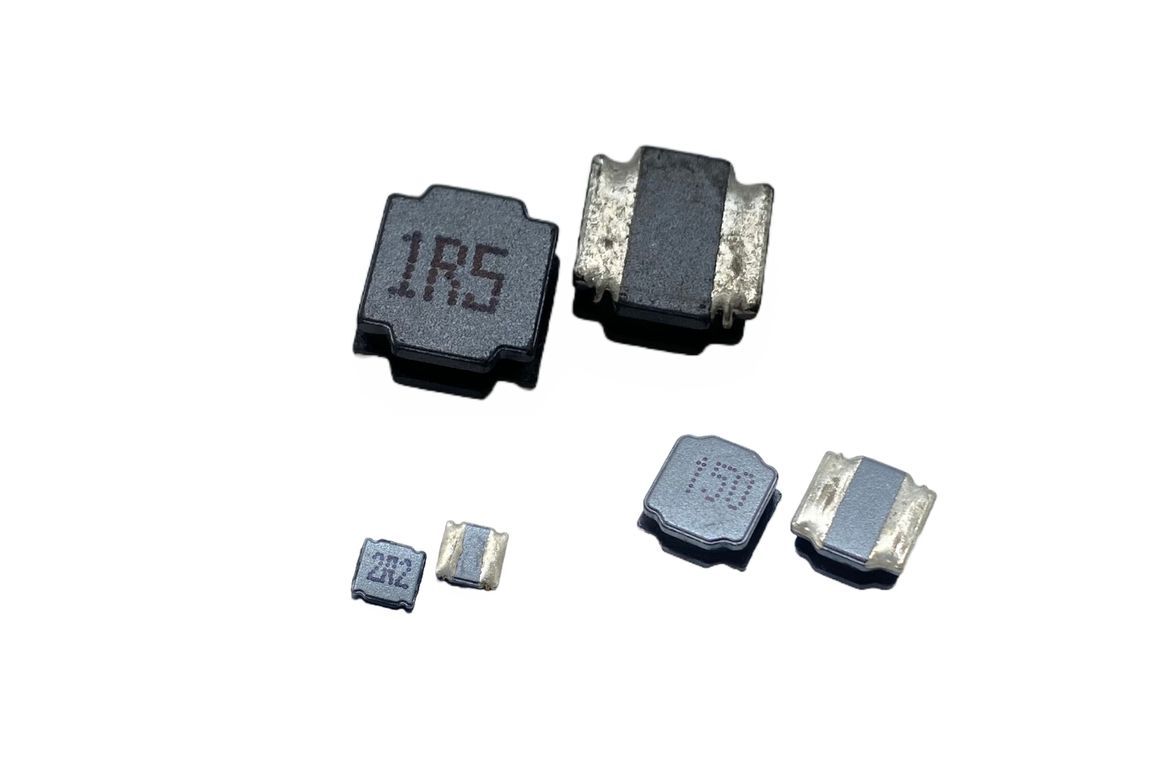

SMD Semi-shielded Power Inductor

SMD Semi-Shielded Power Inductors Cost Effective Solutions, SMD Resin Shielded Power Inductor

SMD semi-shielded inductors offer a unique balance between fully shielded and non-shielded inductors, making them an ideal choice for applications requiring moderate EMI control without the added weight or cost of a completely enclosed design. In these inductors, a wound drum core is covered and molded with magnetic epoxy—an epoxy resin blended with soft magnetic metal powder. This construction functions similarly to a ring core in fully shielded solutions, but does not completely enclose the winding, resulting in a more compact and lighter component compared to fully shielded inductors.

With SMD semi-shielded inductors, engineers can effectively reduce EMI while optimizing weight, board space, and overall cost. By leveraging either ferrite or alloy powder cores, these inductors cater to a broad spectrum of power designs, providing a convenient middle ground between fully shielded and non-shielded configurations.

Features

- Magnetic Epoxy Shield:Acts as a partial shield to reduce EMI while allowing for a smaller, lighter package. / Helps maintain the inductor’s stability and performance throughout its operating life.

- Moderate Flux Radiation & Cost-Effectiveness:Provides medium-level flux radiation and space efficiency at a lower cost than fully shielded inductors. / Offers better EMI performance than non-shielded types, striking a cost–performance balance. / A practical choice for less radiation-sensitive applications where moderate EMI containment is sufficient.

- Broad Dimension Range & Customization: Available in various package sizes from 2.0 mm to 8.0 mm, accommodating diverse layout requirements. / Custom inductance values can be developed to meet specific design criteria or unique application needs.

Applications

- Consumer Electronics demanding smaller form factors yet decent EMI suppression

- Power Modules, DC-DC Converters, and Battery-Powered Devices needing reduced heat generation and stable operation

- Automotive Subsystems where moderate EMI performance is sufficient, plus space and cost considerations are critical

- Industrial Controls requiring balance between cost, size, and electromagnetic compatibility

| Image | name | Size(mm) | Inductance(uH) | Isat(A) | Irms(A) | DCR(mΩ) | Action |

|---|---|---|---|---|---|---|---|

| 0.24uH 4.5A Semi-shielded inductors | 2.0x1.6x1.0 | 0.24 | 4.5 | 3 | 40 | |

| 0.33uH 4.4A SMD semi-shielded inductors | 2.0x1.6x1.0 | 0.33 | 4.4 | 2.7 | 49 | |

| 0.47uH 4A Surface mount semi-shielded inductors | 2.0x1.6x1.0 | 0.47 | 4 | 2.7 | 49 | |

| 0.68uH 3.5A Miniature semi shielded inductors | 2.0x1.6x1.0 | 0.68 | 3.5 | 2.5 | 65 | |

| 1uH 3.3A Resin-shielded inductors | 2.0x1.6x1.0 | 1 | 3.3 | 2 | 95 | |

| 1.5uH 1.95A SMD resin-shielded inductors | 2.0x1.6x1.0 | 1.5 | 1.95 | 1.7 | 130 | |

| 2.2uH 1.9A Epoxy-sealed inductors | 2.0x1.6x1.0 | 2.2 | 1.9 | 1.4 | 180 | |

| 3.3uH 1.4A Resin-coated inductors | 2.0x1.6x1.0 | 3.3 | 1.4 | 1.1 | 307 | |

| 4.7uH 1.1A 201610 Resin-shielded inductors | 2.0x1.6x1.0 | 4.7 | 1.1 | 0.9 | 425 | |

| 6.8uH 0.95A 201610 Miniature semi shielded inductors | 2.0x1.6x1.0 | 6.8 | 0.95 | 0.7 | 620 | |

| 8.2uH 0.86A 201610 Surface mount semi-shielded inductors | 2.0x1.6x1.0 | 8.2 | 0.86 | 0.66 | 870 | |

| 10uH 0.8A 201610 SMD semi-shielded inductors | 2.0x1.6x1.0 | 10 | 0.8 | 0.6 | 875 |

SMD Semi-shielded Power Inductor | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, SMD Semi-shielded Power Inductor, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.