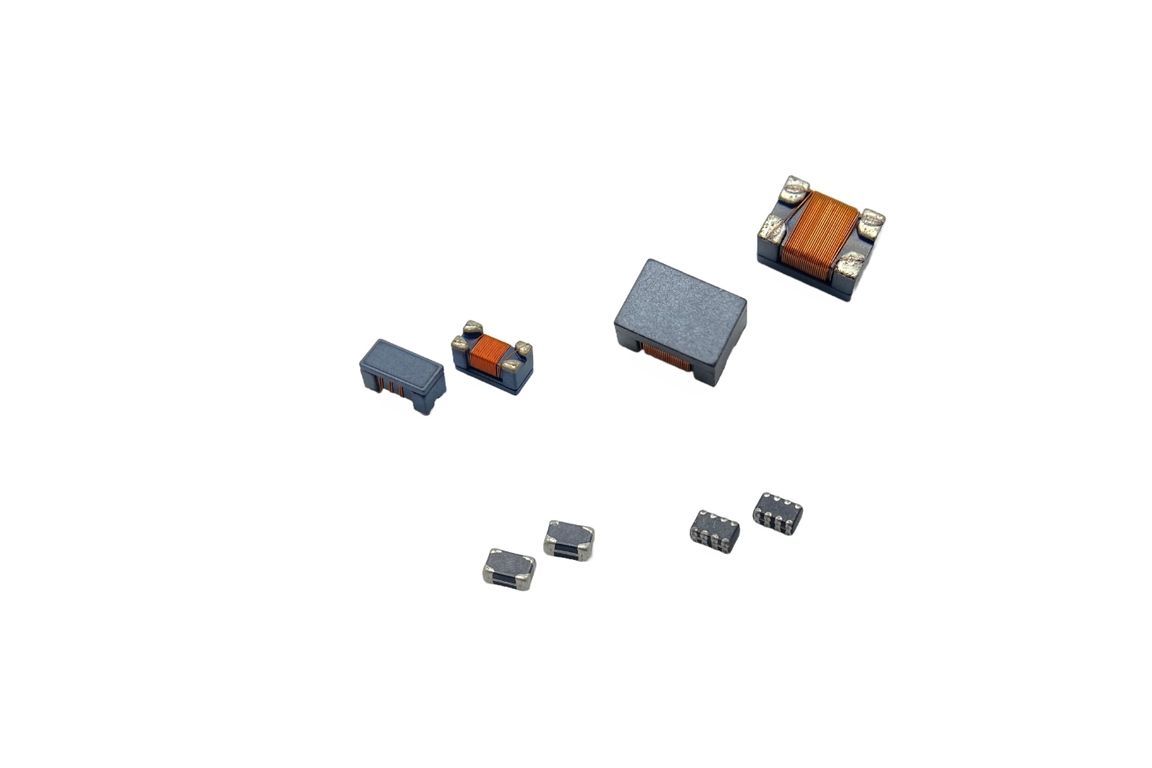

High Frequency SMD Common Mode Choke - MM SERIES

Common mode choke for Controller Area Network (CAN BUS) or other high frequency applications

The SMD high-performance surface mount common mode choke is available in various industry-standard dimensions and constructions. The smallest size of wire wound common mode choke ranges from 1005 (0402) to 4532 (1812). The MM series of wire-wound common mode chokes is designed to eliminate common-mode noise from DC lines over a broad range of frequencies. The smaller size of MM2012 (0805) is suitable for high-speed data line applications with low insertion loss and differential impedance. The wire-wound common mode choke has a 1:1 impedance ratio or balun structure with different turn ratios. It can work in high frequencies up to GHz with a standard insertion loss of only 0.8 dB, making it suitable for USB2.0, HDMI 2.0, USB 3.0, IEEE 1394, and LVDS applications.

As more electronic components are applied to automobiles, most signals are transmitted via LAN cables connecting these ECUs. To combat noise and make components suitable for this kind of environment, noise suppression has become crucial for safety reasons. Common-mode chokes are frequently used to suppress electromagnetic compatibility (EMC) and increase system reliability. The SMD common mode filter MM series utilize the NiZn core and can be used to filter common-mode noise across a broad range of frequencies and can provide low DC resistance and higher current-carrying capacity. Common-mode chokes are not only available for automotive applications but also for other general industrial applications that require higher quality/characteristics. The whole series is RoHs, REACH compliance, and halogen-free.

Function of common mode choke

Unshielded electronics, inverters, or other unwanted signals often result in common-mode noise current, and a common-mode choke is usually the best choice to filter/suppress these unwanted noises in electrical circuits to avoid interference problems. The common-mode choke works like a filter in the circuit and has two windings with a 1:1 turn ratio and can work in both normal and differential modes. As a common mode, the current will flow through the two windings in the same direction, which means the magnetic flux will boost each other, generating inductance to impede common-mode current. On the other hand, in differential mode, the current travels from one line from the source to the load and returns in the opposite direction as the complete circuit. The magnetic flux is canceled, and the current can pass directly.

Features

- Effective in high frequency noise suppression.

- Without degrading the signal.

- Suppress the common mode noise on electronics products

- Excellent common mode impedance at high frequency to suppress the noise.

| Image | name | Size(mm) | Inductance(uH) | Isat(A) | Irms(A) | DCR(mΩ) | Action |

|---|---|---|---|---|---|---|---|

| 12Ω, 0.1A Multilayer Common Mode Choke Coils | 0.85x0.65x0.40 | 0.1 | 2500 | |||

| 33Ω, 0.1A thin film common mode filter | 0.85x0.65x0.40 | 0.1 | 2500 | |||

| 47Ω, 0.1A Ultra-Compact Common Mode Chokes | 0.85x0.65x0.40 | 0.1 | 5000 | |||

| 90Ω, 0.1A wide-band Common Mode Chokes | 0.85x0.65x0.40 | 0.1 | 6500 | |||

| 65Ω, 0.1A thin film common mode choke for EMI suppression | 1.0x1.25x0.60 | 0.1 | 4000 | |||

| 90Ω, 0.1A Multilayer dataline common mode choke coils | 1.0x1.25x0.60 | 0.1 | 4000 | |||

| 50Ω, 0.1A Miniaturized thin-film common-mode filters | 1.25x1.0x0.85 | 0.1 | 1500 | |||

| 90Ω, 0.2A compact common mode filter for high-speed differential signal lines | 1.25x1.0x0.85 | 0.2 | 1450 | |||

| 120Ω, 0.3A Bead arrays | 2.0x1.0x0.55 | 0.3 | 300 | |||

| 240Ω, 0.3A Chip arrays signal filtering | 2.0x1.0x0.55 | 0.3 | 400 | |||

| 300Ω, 0.2A Low frequency chip beads | 2.0x1.0x0.55 | 0.2 | 600 | |||

| 470Ω, 0.2A Chip array ferrite beads | 2.0x1.0x0.55 | 0.2 | 900 |

High Frequency SMD Common Mode Choke - MM SERIES | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, High Frequency SMD Common Mode Choke - MM SERIES, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.