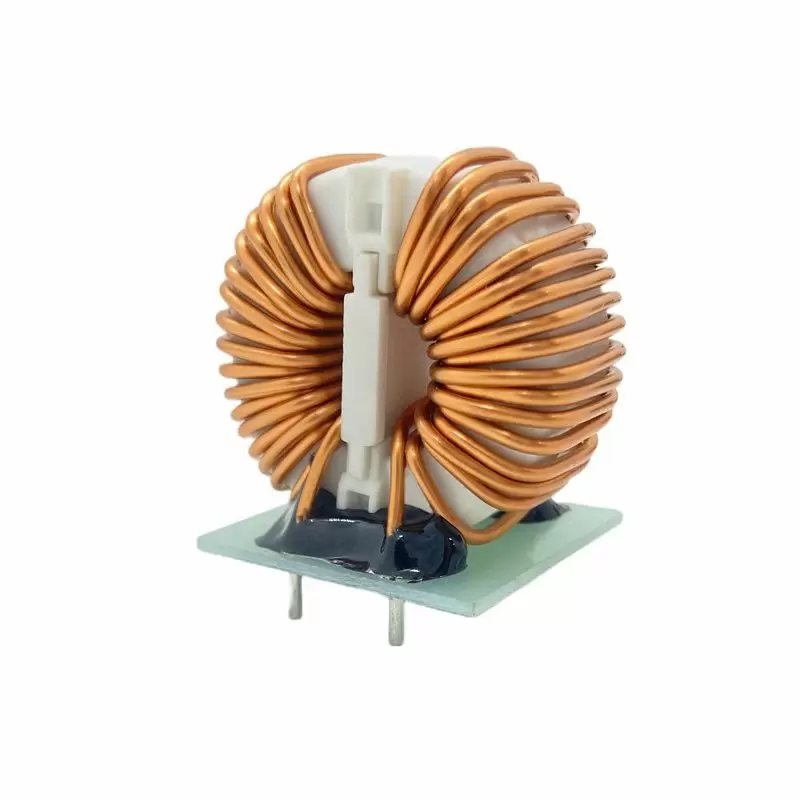

Molding High Current Power Inductors

Molded Power Choke with Carbonyl / Alloy / Iron Powder

SMD molded power inductor, also called molding high current power inductor, utilizes molding technology to cover the coil and has high magnetic shielding effectiveness with low magnetic flux leakage, no acoustic noise and soft saturation current. There are several advantages of molded inductors, such as better protection against environmental factors. For instance the effect of moisture, dust, and vibration. Compared to other types of power inductor such as assembling shielded inductor, and epoxy resin shielded inductor, the molded inductors are typically more durable and reliable, making them well-suited for use in harsh or demanding environments. Due to the construction of the molded power inductor, they also offer improved mechanical stability, which can be beneficial in applications where the inductor is subjected to high levels of vibration or shock. Additionally, the molded inductors is featured with a simple structure that can be designed to be more compact and lightweight than other types of power inductors, which can be beneficial in certain applications where space is limited, or weight is a concern.

The molding power inductor SEP/REP model features with low profile (from 1.2mm to 7.0mm) and a small footprint (from 2.5mm). Due to our advanced powder and wire winding technology, the product has a small inductance change depending on temperature. Compared to the ferrite structure, molding power choke - SEP series have soft saturation characteristics and better efficiency.

Traditional molded high current inductor utilizes the round wire. To achieve better performance and lower energy consumption, the flat wire is also available for the SMD molded power inductor. The molding power inductor with flat wire has a 40~60% better surface area, this is helpful for larger current goes through and provides lower dc resistance. The vast range of inductance values, from 0.1 uH to 220 uH. (Another custom request inductance value is available).

Unique powder / winding technology from us

Our engineer team have excellent background for material powder and winding technology. The molded high current inductor is made using two proprietary materials: carbonyl and alloy powder. Carbonyl powder provides a higher saturation point, lower power loss, and a more durable structure, while alloy powder is more cost-effective and has a simpler production process that is more environmentally friendly. Both materials have low inductance changes with temperature and do not reach magnetic saturation, making the inductor suitable for applications that require stable inductance values at high currents and frequencies. The inductance value decreases slightly above rated currents, and DC/DC energy storage is possible up to 1 MHz.

Features

- Wide range of operating temperature: -40 °C to +125 °C / +155 °C

- Highest possible saturation current without saturation

- Excellent noise suppression

- Frequency range up to 5 MHz

| Image | name | Size(mm) | Inductance(uH) | Isat(A) | Irms(A) | DCR(mΩ) | Action |

|---|---|---|---|---|---|---|---|

| 2.2uH, 3A Low profile lloy powder molding power inductor | 2.5x2.0x1.2 | 2.2 | 3 | 2.27 | 98 | |

| 3.3uH, 2.4A Low profile lloy powder molding power inductor | 2.5x2.0x1.2 | 3.3 | 2.1 | 2.4 | 150 | |

| 4.7uH, 1.9A Low profile SMD alloy molding high power inductors | 2.5x2.0x1.2 | 4.7 | 1.9 | 1.61 | 235 | |

| 6.8uH, 1.45A Low profile SMD alloy molding high power inductors | 2.5x2.0x1.2 | 6.8 | 1.45 | 1.1 | 375 | |

| 10uH, 1.1A Low profile SMD alloy molding high power inductors | 2.5x2.0x1.2 | 10 | 1.1 | 0.88 | 450 | |

| 0.47uH, 6.8A Low profile SMD molding power inductor | 2.5x2.0x1.2 | 0.47 | 6.8 | 5.8 | 22 | |

| 1uH, 4.8A Low profile SMD molding power chokes | 2.5x2.0x1.2 | 1 | 4.8 | 3.9 | 44 | |

| 2.2uH, 3.5A Low profile molding power inductors | 2.5x2.0x1.2 | 2.2 | 3.5 | 2.5 | 89 | |

| 0.1uH, 13.5A Molded Power Inductor | 2.5x2.0x1.2 | 0.1 | 13.5 | 12 | 10 | |

| 0.15uH, 13A High-Current Inductor | 2.5x2.0x1.2 | 0.15 | 13 | 11.5 | 11 | |

| 0.22uH, 9.6A Low DCR Inductor | 2.5x2.0x1.2 | 0.22 | 9.6 | 8.2 | 14 | |

| 0.24uH, 9.3A High Saturation Current Inductor | 2.5x2.0x1.2 | 0.24 | 9.3 | 8 | 15 |

Molding High Current Power Inductors | High Current Power Inductor Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, Molding High Current Power Inductors, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.