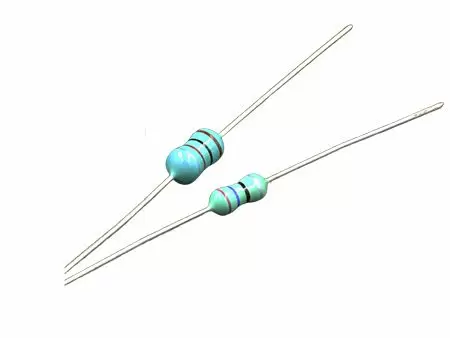

100uH, 0.275A epoxy resin coating axial leaded inductor

AL0410-101K-LF

100uH, 0.275A axial through hole fixed power inductor

100uH, 0.275A epoxy resin coating axial leaded inductor with dimension 4.0x10.0mm. Utilize the high performance ferrite core and treated epoxy resin coating to achieve the high Q factor and SRF (self-resonant frequencies). The epoxy resin coating not only provide the better protection for high inductance value of this axial leaded power inductor, better resistance to humidity resistance and ensure long life. The epoxy conformal coated power inductor featur with wide range of inductance value and light weight.

Customization

Due to the solid background of our engineer team at ferrite powder territory, we could modify the core powder, design and produce the most suitable product to fit customer's applications. Except for the standard characteristic of our series specification, Coilmaster Electronics also offer the customization product with low minimum order quantity (MOQ), tighter tolerance, different inductance and frequency applications.

Leadtime

Coilmaster’s standard lead time is 6~8 weeks, in urgent case, the fast delivery program is available. For specific product series, we could send out the goods within 10 or 20 working days.

Key features

- Conformal coated inductors

- Epoxy resin coating with better protection

- Wide inductance range

- Special magnetic core structure

- High Q and high SRF value

- Tape and reel packing

- Operating temperature range: -40℃~+125℃

- Low cost designed

Applications

- Television

- PC personal computers

- Radio

- Cell phone

- DC-DC converter

- IOT (Internet of Things)

Construction

- Unshielded Inductor

Size(mm)

- 4.0x10.0

Inductance(uH)

- 100

Inductance tolerance

- ±10%

Test Frequency(MHz)

- 2.52

Isat(A)

- 0.275

Irms(A)

- 0.275

DCR(mΩ)

- 2500

Q(Ref)

- 30

SRF(MHz)

- 4.8

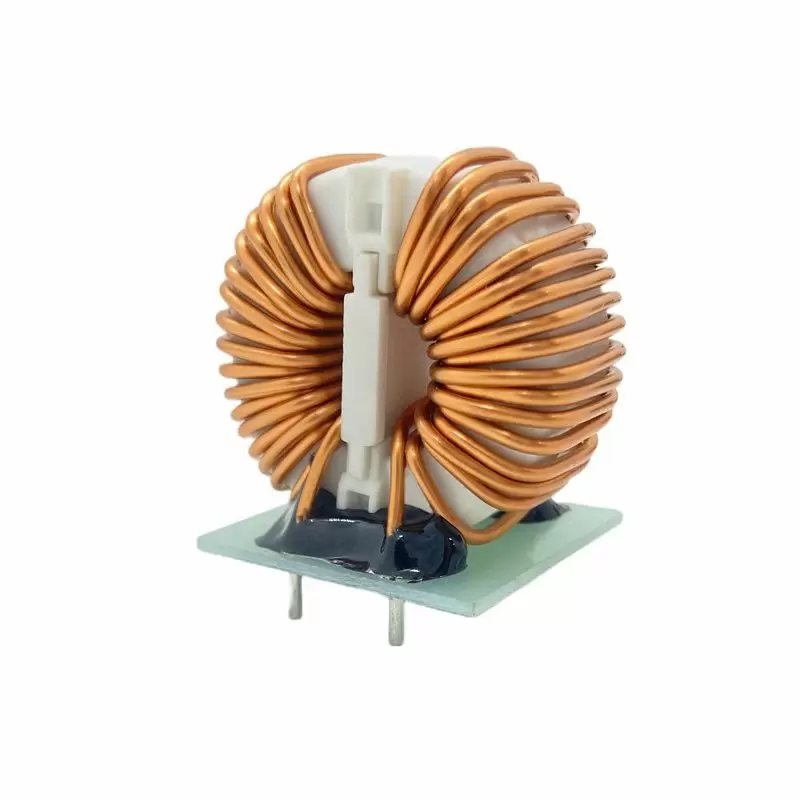

- Related Product

15uH, 3.3A Unshielded wire-wound SMD power inductor

SDB1204-150M-LF

15uH, 3.3A Unshielded wire-wound SMD power inductor with dimension 13.0x13.0x5.1mm. SDB series...

Details Add to List100uH, 0.6A Low profile SMD choke coils

SDR53-101K-LF

100uH, 0.6A Low profile SMD choke coils, small design of only 5.8x5.2x2.5mm. Various high power...

Details Add to List10uH, 4.4A Magnetically Shielded Power Inductor

SDC104R-100N-LF

10uH, 4.4A SMD Magnetically Shielded Power Inductors with dimension 10.3x10.5x4.0mm. The SMD magnetically...

Details Add to List- Download

100uH, 0.275A epoxy resin coating axial leaded inductor | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 100uH, 0.275A epoxy resin coating axial leaded inductor, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.