Automotive 1000Ω 1.5A 2012 chip ferrite bead for high-frequency noise reduction

MI2012-102-1.5A-LF-A

Automotive 1000Ω 1.5A 2012 chip ferrite bead for power line

Automotive grade 1000Ω 1.5A 2012 chip ferrite bead for power line, this multilayer high current ferrite chip bead is available in a variety of sizes from 0603(0201) to 8530(3312) and wide range of specifications ensuring durable and trouble-free use. A ferrite bead is a passive electric component (multilayer chip beads) is that suppresses or filter high frequency noise in electronic circuits. Ferrite beads employ the dissipation of high frequency currents in a ferrite ceramic to build high frequency noise suppression devices. the SMD ferrite bead could transfer the high frequency noise into heat and ferrite beads may also be called blocks, cores, rings, EMI filters, or chokes. EMI multilayer ferrite chip bead is easy to use in various applciations due to several reasons. SMD Ferrite beads are the most widely used EMI suppression component for two fundamental reasons: A) cost-effective B) easy to add to the circuit because of the small size C) broad range with various features and benefits.

Customization

Due to the solid background of our engineer team at ferrite powder territory, we could modify the core powder, design and produce the most suitable product to fit customer's applications. Except for the standard characteristic of our series specification, Coilmaster Electronics also offer the customization product with low minimum order quantity (MOQ), tighter tolerance, different inductance and frequency applications.

Leadtime

Coilmaster’s standard lead time is 6~8 weeks, in urgent case, the fast delivery program is available. For specific product series, we could send out the goods within 10 or 20 working days.

Key features

- Cost-effective

- High rated current

- Closed magnetic circuit avoids crosstalk

- High impedance

- Miniature dimension

- Excellent High Frequency EMI filter

- Available reflow soldering

- High density installation

Applications

- Lighting Systems(high-intensity discharge (HID, high-power LED

- Infotainment and Audio Systems

- Inverter and Converter Circuits(EVs and hybrids)

- Power Supply Lines(electric power steering or electric vehicle (EV) charging systems)

- GPS systems

Construction

- Automotive Chip Beads

Size(mm)

- 2.2x1.4x1.1

Test Frequency(MHz)

- 100

Impedance tolerance

- ±25%

Irms(A)

- 1.5

DCR(mΩ)

- 120

Impedance(Ω) at 100MHz

- 1000

- Related Product

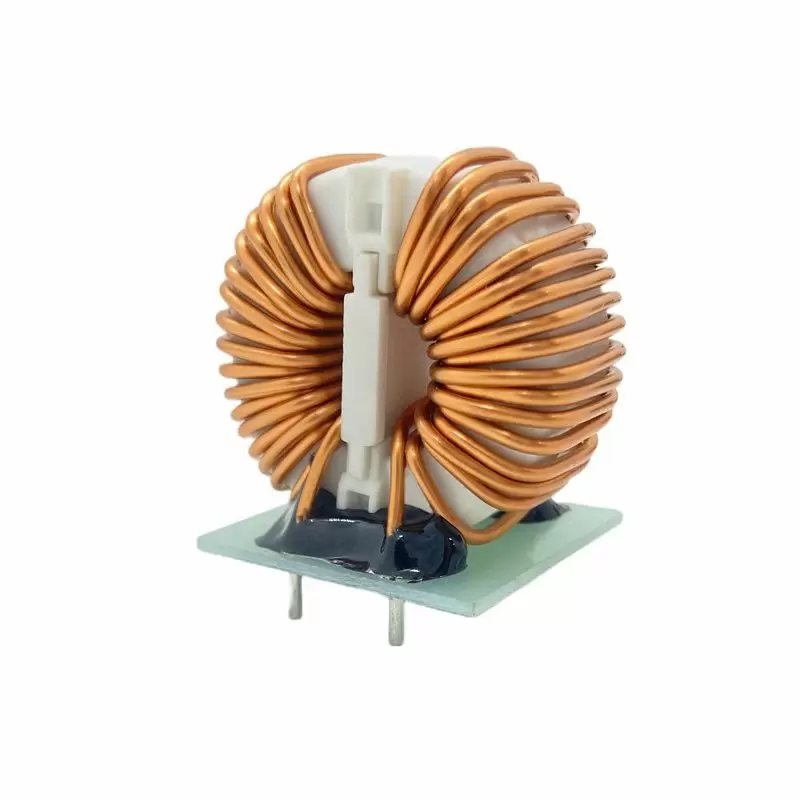

56uH, 1.55A Unshielded wire-wound high current SMT power inductor

SDH3316-560M-LF

56uH, 1.55A Unshielded wire-wound high current SMT power inductor with dimension 13.21x9.91x6.35mm....

Details Add to List18uH, 0.72A Low EMI Shielded SMD Power Inductor

SDC4D28-180N-LF

18uH, 0.72A Wirewound Ferrite Shielded SMD Power Inductors with dimension 5.0x5.0x3.0mm. The SMD magnetically...

Details Add to List150uH, 0.35A SMT unshielded wirewound power inductor

SDB0703-151M-LF

150uH, 0.35A SMT unshielded wirewound power inductor with dimension 7.0x7.0x3.0mm. SDB series...

Details Add to List- Download

Automotive 1000Ω 1.5A 2012 chip ferrite bead for high-frequency noise reduction | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, Automotive 1000Ω 1.5A 2012 chip ferrite bead for high-frequency noise reduction, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.