1.2uH, 4.5A Inductor for Power Electronics

ML252012EM-1R2M-LF

1.2uH, 4.5A High-Performance Inductor

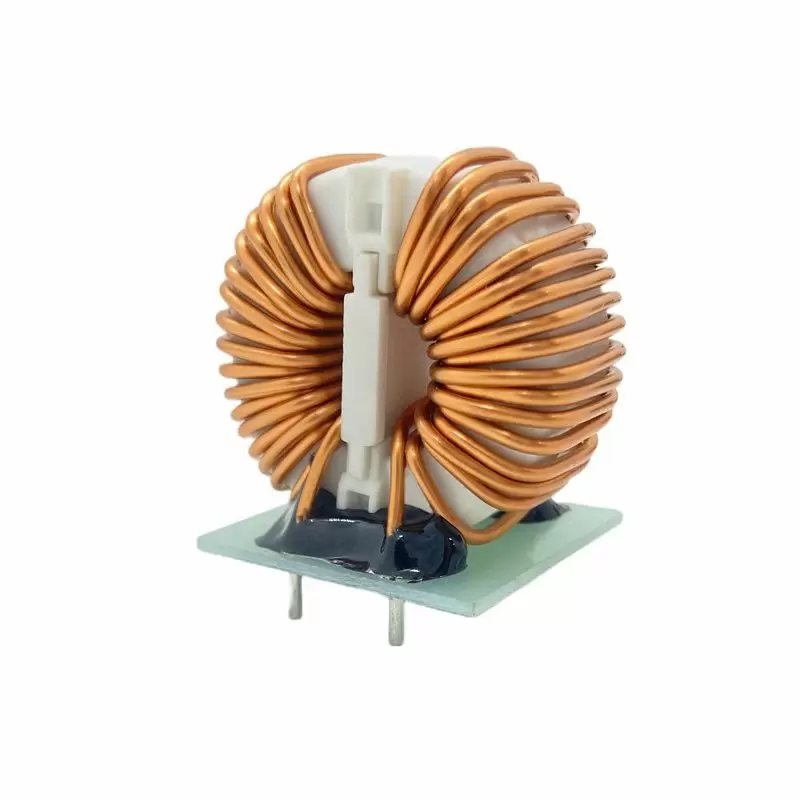

Introducing our high-performance molded power inductor, specifically designed to set new standards in compact inductor technology. With a compact footprint of just 2.5 x 2.0 x 1.2 mm and an inductance value of 1.2µH, this inductor delivers exceptional performance compared to typical market alternatives. Featuring a low DCR of 45mΩ max and a high saturation current of 4.5A, it ensures efficient power handling and minimal energy loss, making it an ideal choice for engineers and product developers aiming to maximize performance in space-constrained applications.

Our molded power inductor addresses the critical challenges engineers and sourcers often face, such as the demand for reliable high-current handling and effective thermal management in compact designs. The low DCR reduces energy loss and improves efficiency, which is vital for applications where minimizing heat generation is essential to maintaining long-term stability and reliability. With its enhanced saturation current, this inductor outperforms standard models by offering greater current handling capabilities without the risk of core saturation, ensuring consistent performance even under high-stress conditions, such as those found in automotive and industrial environments where compliance with stringent safety and efficiency standards is mandatory.

To cater to a wide range of application needs, Coilmaster Electronics offers customizable solutions that enable precise adjustments to inductance, DCR, and size, allowing for optimization based on specific project requirements. Our engineering team is ready to collaborate with you to develop a tailored solution that aligns perfectly with your needs, whether it’s enhancing electromagnetic compatibility, reducing footprint, or meeting tight regulatory standards. This flexibility, combined with our unwavering commitment to quality and performance, makes our molded power inductors the perfect choice for your next innovative project.

Customization

At our company, we offer extensive customization options for our molded power inductors to meet the unique requirements of your applications. Whether you need adjustments in inductance, DCR, size, or material composition, our expert engineering team is here to develop a solution tailored specifically to your project’s needs. We provide flexibility in selecting powder materials and core configurations to optimize performance, ensuring your inductors deliver maximum efficiency, thermal stability, and current handling capabilities. Choose our customizable inductors for solutions that perfectly align with your design goals, enhancing both functionality and cost-effectiveness. Contact us today to explore how we can customize our inductors to suit your exact specifications.

Leadtime

Coilmaster Electronics understand that time is critical in every project, which is why we prioritize offering competitive lead times for our molded power inductors. Our streamlined production processes and efficient supply chain management enable us to deliver high-quality inductors quickly, helping you meet tight project deadlines without compromising on performance or reliability. Whether you need a standard product or a customized solution, we are committed to ensuring timely delivery to keep your projects on track. Choose our molded power inductors for dependable quality and fast turnaround, so you can accelerate your development cycles and maintain a competitive edge in the market.

Key features

- Compact Size

- Efficient Thermal Management

- Enhanced Noise Suppression

- Reliability and Durability

- Low DCR

Applications

- Switch-mode power supplies (SMPS)

- DDR5 memory modules

- Motor Control Systems

- Electronic Control Units (ECUs)

- Advanced Driver Assistance Systems (ADAS)

- Infotainment Systems

- Wearable Devices

Construction

- Shielded Inductor

Size(mm)

- 2.5x2.0x1.2

Inductance(uH)

- 1.2

Inductance tolerance

- ±20%

Test Frequency(MHz)

- 1

Isat(A)

- 4.5

Irms(A)

- 3.8

DCR(mΩ)

- 45

- Related Product

67Ω, 0.4A Low profile SMD USB common mode choke

MM2012-670-LF

67Ω, 0.4A Low profile SMD USB common mode choke utilize the ferrite powder as the core body....

Details Add to List120ohm 3A 0603 chip ferrite bead for power line

MI1608-121-3A-LF

Coilmaster Electronics takes pride in delivering high-performance solutions to meet the evolving...

Details Add to List7.5nH, 0.7Amps 0603 Miniature SMD High Q factor Power Inductor

MS1608-7N5K-LF

7.5nH, 0.7Amps 0603 Miniature SMD High Q factor Power Inductor, the body structure is made...

Details Add to List- Download

1.2uH, 4.5A Inductor for Power Electronics | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 1.2uH, 4.5A Inductor for Power Electronics, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.