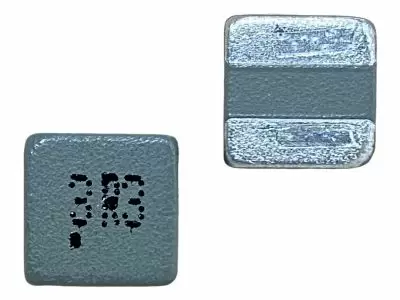

1uH, 7A Low Rdc molded inductors

ML404012M-1R0M-LF

1uH, 7A Molded inductors with vinyl thermal spray

Our 4x4x1.2mm molded SMD power inductor, with 7Amps at 1uH is specifically engineered to excel in automotive applications. Featuring a superior saturation current that’s 15-20% better than competitors, it provides exceptional performance in managing high current loads and ensuring reliable operation under extreme conditions. Its low DC resistance (DCR) enhances power efficiency, reducing heat generation and improving overall system reliability. Ideal for automotive control units and power management systems, this inductor delivers unparalleled stability and durability where it's needed most.

The reduced DCR of our 4x4mm inductor significantly improves energy efficiency and reduces power loss, crucial for high-performance applications. Its superior saturation current capability ensures stable performance even under peak loads, which is essential for demanding environments. This inductor stands out for its ability to deliver consistent and reliable performance, making it a top choice for both automotive and industrial applications.

We adhere to rigorous quality standards, with extensive reflow and withstand voltage testing to ensure each inductor meets top-tier performance criteria. Our commitment to quality is matched by our ability to offer customization options, allowing you to tailor the inductor to specific application needs—whether automotive, industrial, or consumer. Our solutions are designed to integrate seamlessly into your systems, providing unmatched versatility and reliability.

Customization

Our 4x4mm molded SMD power inductor can be customized to meet your specific requirements. We offer adjustments in inductance characteristics and dimensions, with options to accommodate tooling costs. Additionally, we can utilize different core materials to optimize working frequencies or switching frequencies according to your application needs. Whether you need precise tuning for performance or a specific size to fit your design, our flexible customization ensures that you receive a solution perfectly aligned with your technical and operational demands.

Leadtime

We prioritize efficiency in our production process to provide you with reliable lead times. Our streamlined manufacturing and logistics ensure that you receive your 4x4mm molded SMD power inductors promptly, minimizing downtime and accelerating your project timelines. Whether you require standard or expedited delivery, we are committed to meeting your deadlines with consistent and dependable service. Partner with us for a smooth and timely integration of our components into your systems, helping you maintain your schedule and project goals.

Key features

- Low loss material

- Tight tolerances

- High saturation current

- High efficiency

- Ultra low DC resistance

- Suitable for switching frequency up to 10 MHz

- Customized specification available

Applications

- Automotive power supplies

- Automotive control units

- Automotive lighting

- Automotive infotainment systems

- Industrial control systems

- Network equipment including routers, switches, and base stations, for managing power and filtering signals.

- Medical equipment

Construction

- Shielded Inductor

Size(mm)

- 4.0x4.0x1.2

Inductance(uH)

- 1

Inductance tolerance

- ±20%

Test Frequency(MHz)

- 0.1

Isat(A)

- 7

Irms(A)

- 6.5

DCR(mΩ)

- 43

- Related Product

0.036uH, 0.32Amps 1005 Miniature SMD Wirewound Non-Magnetic Power Inductor

MS1005-36NG-LF

0.036uH, 0.32Amps 1005 Miniature SMD Wirewound Non-Magnetic Power Inductor, the body structure...

Details Add to List2.2uH, 3.8A Inductor for Renewable Energy Systems

ML252012EM-2R2M-LF

Introducing our high-performance molded power inductor, specifically designed to set new standards...

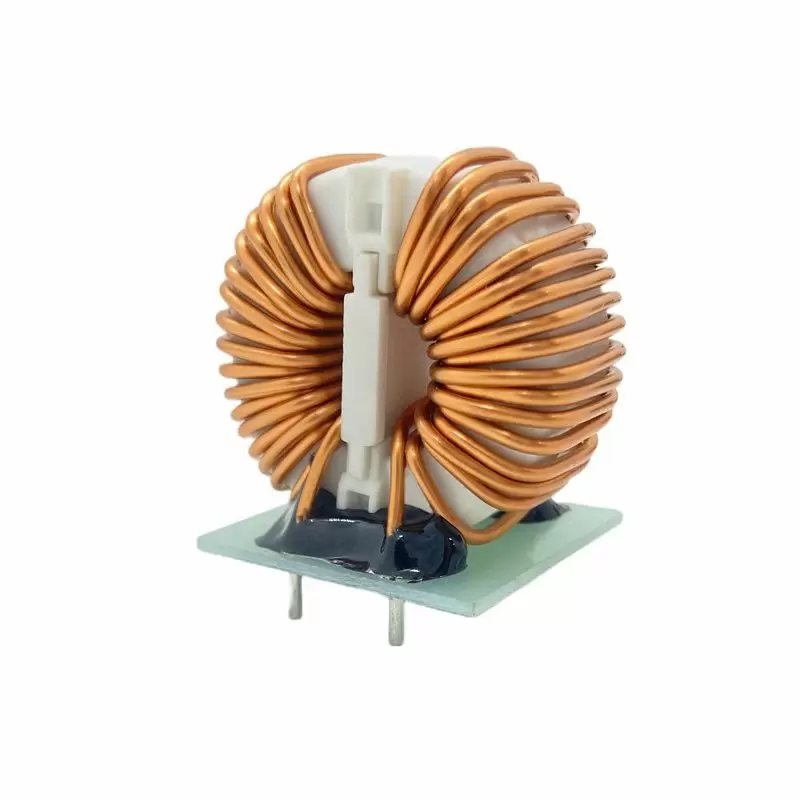

Details Add to List42uH SMD Transformer for PoE

EFD20XFS-0F24L-LF

The EFD20XFS-0F24L-LF SMD POE (Power over Ethernet) transformers are compact and efficient...

Details Add to List- Download

1uH, 7A Low Rdc molded inductors | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 1uH, 7A Low Rdc molded inductors, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.