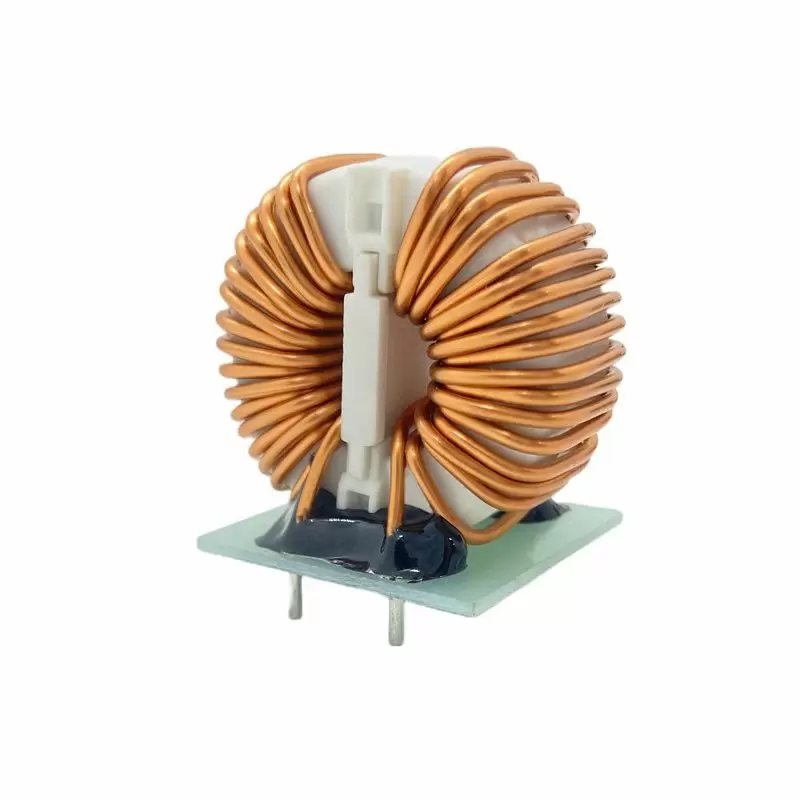

86uH 10.5A high efficiency flat wire THT inductor

REP2918B-860M-LF

86uH 10.5A thermal management inductor

Our high-current flat wire DIP inductors are designed with a ferrite core for exceptional efficiency and low core loss. Capable of handling up to 10.5 amps at 86µH, these inductors offer a wide inductance range from 3.3µH to 100.0µH, with custom values available. The flat wire winding minimizes both DC and AC resistance, reducing energy loss and enhancing overall performance. Fully RoHS and HF compliant, these inductors are ideal for environmentally-conscious industries.

Engineers often face challenges like excessive heat generation and efficiency losses in high-current applications. Our flat wire inductors address these pain points with their superior thermal stability and low resistance, ensuring efficient power management even in demanding environments. The compact vertical mounting further helps designers save space in applications with tight footprints, such as automotive electronics, industrial power systems, and telecommunications equipment.

Ideal for automotive systems, industrial automation, power supplies, and DC-DC converters, our inductors provide reliable performance under heavy loads. With an operating temperature range of -55°C to +130°C, they excel in harsh environments. Whether used in electric vehicle powertrains, telecommunication infrastructure, or renewable energy inverters, these inductors ensure stable, high-efficiency operation, reducing maintenance costs and increasing system longevity.

Customization

Every project is unique, and we offer complete customization options to match your specific requirements. From adjusting inductance values to modifying size, shape, and performance specifications, we collaborate with you to create a solution that perfectly fits your application. Whether you're looking for high-current handling, specialized packaging, or specific environmental performance, our engineering team is ready to provide tailor-made solutions that meet your exact needs.

Leadtime

We know that time is critical in today’s fast-paced industries. That’s why we pride ourselves on offering some of the shortest lead times in the market for our high-current flat wire inductors. Our streamlined production processes and close relationships with our manufacturing partners ensure that your components are delivered on time, keeping your projects on track and helping you meet tight deadlines.

Key features

- Low Core Loss & Efficiency: Leading to improved efficiency, especially in high-power applications.

- High Current Capability: The ability to handle high currents (up to 89 Amps) with minimal loss

- Compact & Space-Saving Design: The vertical mounting and compact footprint, making your product ideal for space-constrained designs.

- Wide Operating Temperature Range : Wide operating temperature range (-55°C to +130°C)

- Thermal Stability: Inductor will operate at high temperatures for extended periods

- Enhanced Durability for Demanding Applications : With superior thermal stability and resistance to mechanical stress

Applications

- Power Supply Units (PSUs): Used in switched-mode power supplies (SMPS) for filtering and energy storage

- Automotive Electronics: Ideal for electric vehicles (EVs), hybrid systems, and powertrain control modules

- Industrial Power Systems: Used in heavy machinery, robotics, and automation systems

- DC-DC Converters: Frequently used in high-efficiency converters for renewable energy systems (solar, wind)

- Inverters: Applied in inverters for solar energy systems, industrial motor drives, and UPS systems

Construction

- Shielded Inductor

Size(mm)

- 27.9x17.8x22.8

Inductance(uH)

- 86

Inductance tolerance

- ±20%

Test Frequency(MHz)

- 0.3

Isat(A)

- 10.5

Irms(A)

- 12

DCR(mΩ)

- 16.17

- Related Product

10200uH, 40A Radial common mode noise filter

CMT3615BF-103N-LF

10200uH, 40A Through hole two wire common mode choke, CMT3615BF series with the dimension 45.72x45.72x24.9mm....

Details Add to List0.47uH, 123A Surface Mount High Efficiency Inductors

SEP1707EA-R47M-LF

The best choice of the SMD high current molding power chokes for high efficiency power converter....

Details Add to List2700Ω, 2A Common mode noise filter

SMM1211-272-LF

2700Ω, 2A Common mode noise filter, this SMT common mode line filter with dimension 12.0x10.8x6.4mm...

Details Add to List- Download

86uH 10.5A high efficiency flat wire THT inductor | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 86uH 10.5A high efficiency flat wire THT inductor, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.

.jpg?v=9fea63a5)