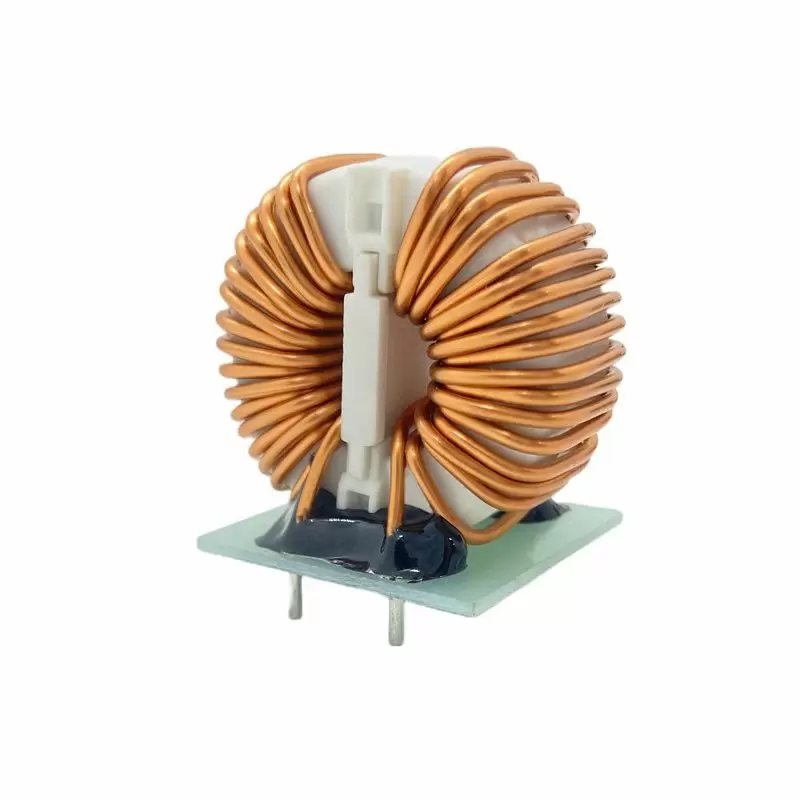

4.7uH 1.05A Semi-shielded surface mount power inductor

SQH3010S-4R7M-LF

1.05A 4.7uH SMD power inductor

When you choose our semi-shielded inductors, you gain access to components that are meticulously engineered for superior quality and performance. Our inductors are designed to enhance your product designs by delivering higher efficiency and meeting the rigorous standards of today's competitive markets. With features such as higher saturation current and lower DC resistance, our semi-shielded SMD power inductors provide excellent performance. For example, at 4.7µH, our inductors can handle up to 1.05 Amps of current without reaching saturation, ensuring reliable operation in high-demand applications.

Built to endure the challenges of both consumer and industrial environments, our inductors offer long-term reliability and durability. The 3.0x3.0x1.0mm size, in particular, is engineered for superior mechanical stability, making it ideal for vibration-prone applications such as automotive electronics and industrial equipment. To guarantee consistent quality and reliability, all of our products undergo a single reflow process and are 100% inspected for layer insulation, inductance, and DC resistance, ensuring they meet the highest standards of quality and stability.

The semi-shielded design offers an optimal balance between EMI suppression and compact size, effectively minimizing electromagnetic interference without the need for a fully shielded component. This makes our inductors particularly suitable for applications where both high performance and space efficiency are crucial, ensuring your designs achieve the desired balance of functionality and form.

Customization

Our customization process is designed to address common challenges faced by engineers and sourcing professionals, such as fitting components into compact spaces, meeting stringent electrical specifications, and ensuring compatibility with high-frequency applications. We provide a collaborative approach, offering design flexibility to modify dimensions, materials, and electrical characteristics to match your exact requirements. Our goal is to deliver high-quality, tailored solutions that enhance the performance and reliability of your products while reducing overall development time and costs.

Leadtime

Our semi-shielded SMD inductors, offer a significant lead time advantage, ensuring your projects stay on schedule and within budget. With a streamlined production process and a well-established supply chain, we can deliver high-quality inductors faster than many competitors, reducing downtime and accelerating time-to-market for your products. Whether you are sourcing for automotive, industrial, or consumer electronics, our commitment to quick and reliable lead times ensures you get the components you need when you need them, allowing for greater flexibility in your production planning and inventory management.

Key features

- Better Heat Dissipation: The increased size provides a larger surface area, which helps in dissipating heat mBroad Range of Applications: Due to their combination of size, cost, and performance, semi-shielded inductors are suitable for a wide variety of applications, making them a versatile choice for designers.

- Versatility in Applications: The small size strikes a balance between compactness and performance

- Enhanced Mechanical Strength: The slightly larger form factor can provide better mechanical stability and durability

- Cost-Effective Shielding: Semi-shielded inductors are often less expensive than fully shielded versions, providing a cost-effective solution for moderate EMI reduction needs.

Applications

- Wearable Devices

- Bluetooth and Wi-Fi Modules

- Compact Power Supplies

- LED Drivers

- Automotive keyless entry systems

- DC-DC converters for voltage regulation

Construction

- Semi-Shielded SMD Power Inductors

Size(mm)

- 3.0x3.0x1.0

Inductance(uH)

- 4.7

Inductance tolerance

- ±20%

Test Frequency(MHz)

- 0.1

Isat(A)

- 1.05

Irms(A)

- 1.1

DCR(mΩ)

- 293

- Related Product

2.2uH, 5A SMD Low Profile, High Efficiency Power Inductors

SEP0402EE-2R2M-LF

SMD molding power inductor with low profile 2.1mm. Typically the molded power choke need to support...

Details Add to List30ohm 8.5A 0805 chip ferrite bead for power line

MI2012-300-8.5A-LF

Coilmaster Electronics takes pride in delivering high-performance solutions to meet the evolving...

Details Add to List0.0062uH, 0.76Amps 1005 Miniature SMD High Q factor Power Inductor

MS1005-6N2S-LF

0.0062uH, 0.76Amps 1005 Miniature SMD High Q factor Power Inductor, the body structure is made...

Details Add to List- Download

4.7uH 1.05A Semi-shielded surface mount power inductor | Magnetic components | Transformer, Inductor, Choke Manufacturer | Coilmaster Electronics

Located in Taiwan since 1995, Coilmaster Electronics Co., Ltd. has been a manufacturer of magnetic components. Its main magnetic components include, 4.7uH 1.05A Semi-shielded surface mount power inductor, common mode chokes, SMD molding power chokes, chock coil inductors, SMD shielded and semi-shielded power inductors, low profile and high current power inductors, high voltage power inductors, ethernet and LAN power transformers, flat wire inductors, RJ45 jacks with integrated magnetics and high frequency transformers, and ceramic or air coil multilayer chip inductors.

Coilmaster is a professional manufacturer for inductor, common mode choke, chip beads and transformer. Our vision is “Creating high-performance inductors, reducing energy loss, and contributing to sustainable” To achieve this, our engineer team is keen to design the power inductor to have better efficiency. With more than 20 years of experience in magnetic territory, Coilmaster Electronics is specialized in the production of SMD power inductors, common mode choke, high frequency transformers.

Coilmaster Electronics has been providing customers with high current power inductors since 1995, with both advanced technology and 29 years of experience, Coilmaster Electronics ensures that each customer's requirements are met.